Pumps and compressors for efficiently stripping NGL's from natural gas

Cryogenic Processing

A cryogenic processing plant, also referred to as a striping plant, is a facility where natural gas flowing from wells is cooled to sub-zero temperatures (-120 degrees Fahrenheit, -84 degrees Celsius) in order to condense liquids that naturally occur within the natural gas. These liquids are referred to as NGL’s or Natural Gas Liquids. Sundyne OH2, OH3 and OH 5 process pumps are widely utilized for reliable, safe and efficient transportation of NGL’s once they have been separated from the natural gas. Sundyne integrally geared centrifugal compressors are widely utilized for regeneration of the demethanizer process.

Sundyne Direct Drive Pumps

Sundyne OH3 and OH5 process pumps are widely utilized for reliable, safe and efficient transportation of NGL’s once they have been separated from the natural gas. Sundyne pumps are engineered to meet API 610 / ISO 13709 standards and deliver rugged reliability in a compact footprint.

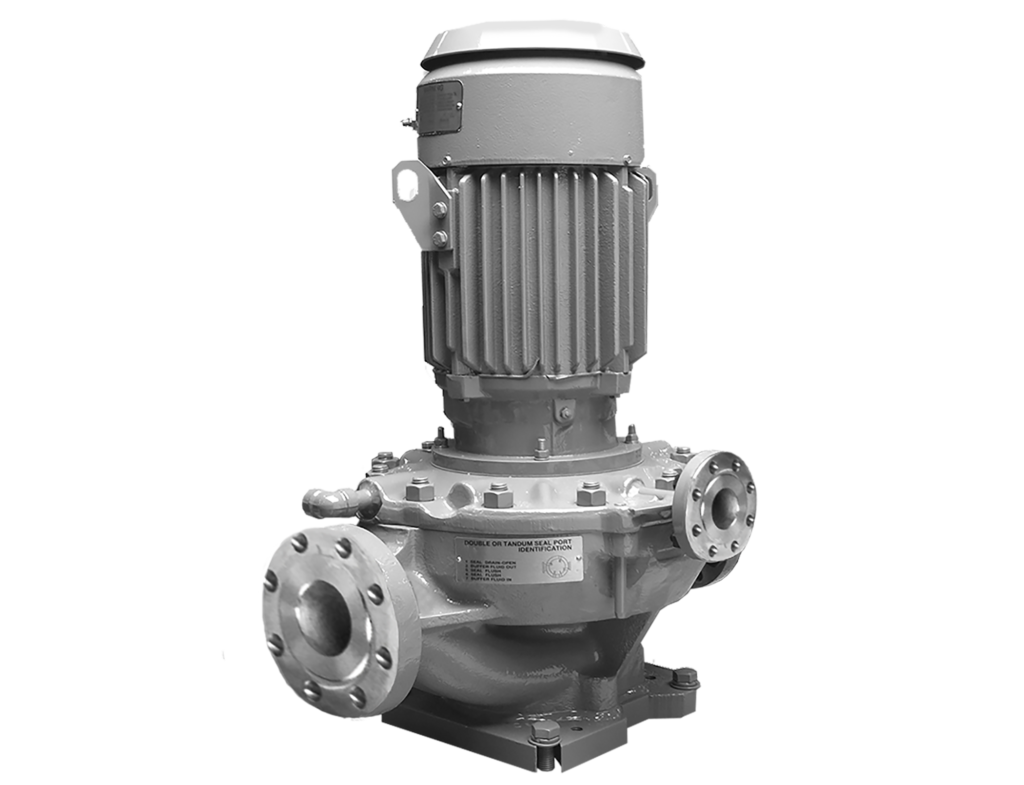

Marelli Process Pumps

OH2 process pumps are widely utilized for reliable, safe and efficient transportation of NGL’s once they have been separated from the natural gas.

Sundyne Process Gas Compressors

Sundyne integrally geared centrifugal compressors are widely utilized for regeneration of the demethanizer process. They can run continuously for 5 years, and their unique modular base plant is easy to install into any process environment.